Supercapacitors

A supercapacitor, also known as an ultracapacitor or electric double-layer capacitor (EDLC), is an energy storage device that bridges the gap between conventional capacitors and batteries. Unlike batteries, which store energy chemically, supercapacitors store energy electrostatically. This enables rapid charging, making them ideal for applications demanding quick energy replenishment. However, their energy density is typically lower than that of batteries, limiting their use for long-term energy storage.

Our supercapacitors have been developed to meet the growing need for sustainable energy storage in wireless electronics. They offer the same benefits as conventional supercapacitors but with improved safety and a reduced environmental footprint – in a compact form factor. They pair perfectly with an energy harvester, minimizing maintenance and maximizing positive impact on the world.

Supercapacitors

Our ultra thin supercapacitors have been developed to meet the growing need for sustainable energy storage in wireless electronics. They offer the same benefits as conventional supercapacitors but with improved safety and a reduced environmental footprint – in a compact form factor. They pair perfectly with an energy harvester, minimizing maintenance and maximizing positive impact on the world.

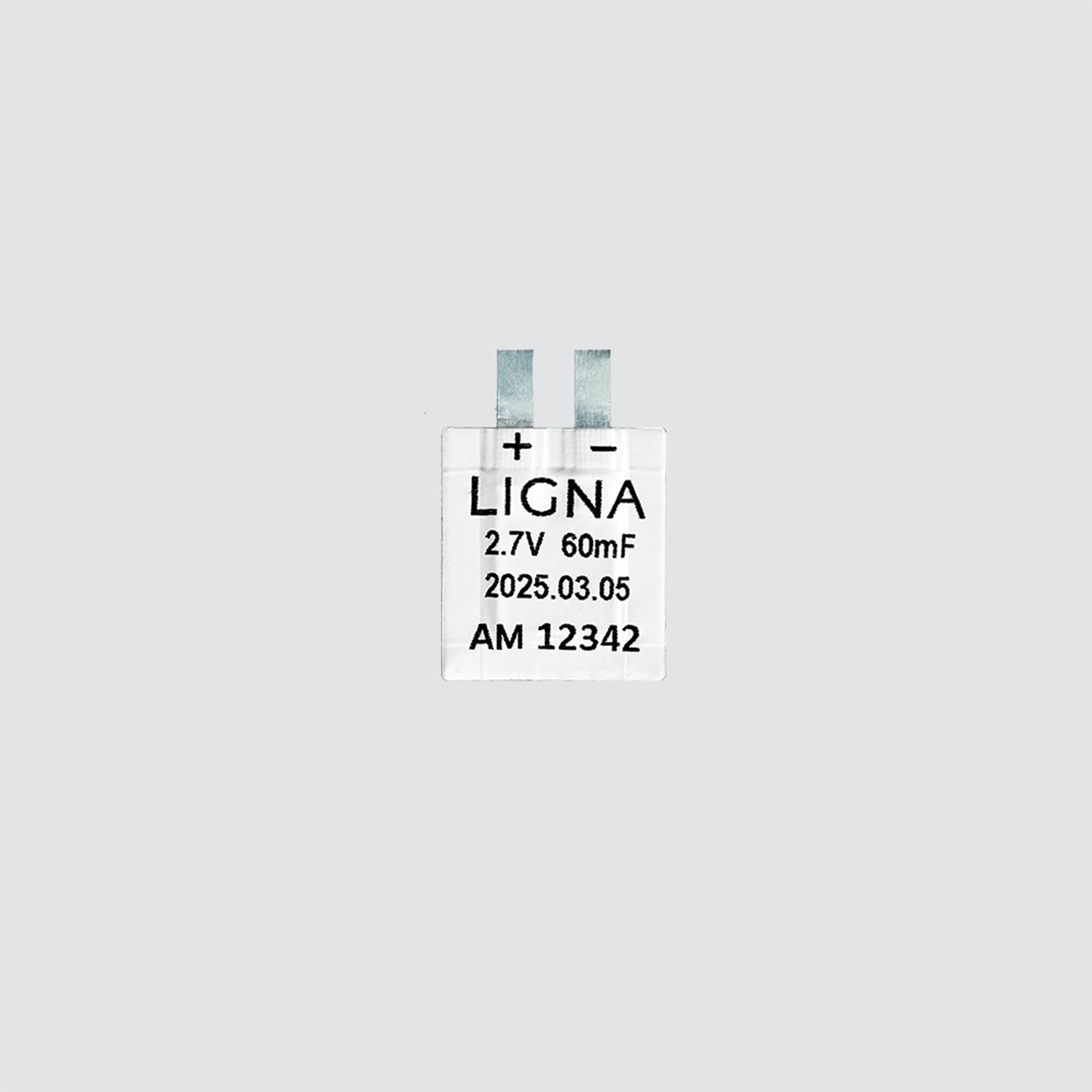

S-Power 2R

With its extreme form factor the 2R ranks among the smallest and thinnest pouch supercapacitors in the world! We have developed this product to meet the requirements for short-term energy storage in active smart cards, but it also does a great job as a battery-support component.

Rated voltage: 2.7 V

Capacitance: 60 mF

Size: 19x22x0.4 mm

Responsibly made from the most sustainable materials, bio-based and no conflict metals

Among the worlds thinnest and most compact supercapacitors

Not flammable nor any toxic chemicals

– for people and environment alike

Our production

At the core of our production process lies a unique approach of roll-to-roll methods that ensures scalability, high automation, minimal material waste and also sets our products apart with their thin form factor.

Slot-die coating

First we formulate our electrode materials into a water-based slurry ready for coating. This slurry is then pumped into a slot-die, which coats it as four stripes on an aluminium foil.

After the slurry has been applied, the coated aluminium passes through a ten meter long dryer to remove all the water. Once dried, the coated aluminium is wound up on a roll at the end of the coating line, making it ready for the next stage of production.

Roll-to-Roll assembly

After the aluminium foil has been coated with activated carbon stripes, it undergoes multiple conversion steps. These steps involve adding barrier foils and a separator, resulting in two electrodes sandwiching the separator, all contained within a layer of barrier foil.

Our flexible conversion line can perform various process steps such as lamination, slitting, and die-cutting, among many others. This flexibility allows us to tailor our processes to meet specific requirements and ensure high-quality output.

Quality control

We strive to maintain and continuously improve the quality of our products. This is ensured by inspection of incoming material, collecting critical in-line data in the manufacturing process as well as testing the final product according to relevant industry standards.

All manufactured cells are subjected to electrical tests and samples are used to confirm reliability preserved over time.

High level of automation – increased production speed compared to batch processes

Scalable – which contributes to our cost-effectiveness

Minimized material waste – leading to a more sustainable, efficient, and cost-effective production line.

Supercapacitors

Knowledge center

If you are interested about learning more about supercapacitors in general, we have gathered some quick insights below. If you find this interesting we have collected some deeper information in two sub sections as well.

Supercapacitors

for energy storage

Supercapacitors offer a compelling solution for short-term energy storage due to their unique characteristics compared to traditional capacitors. While traditional capacitors store energy through the separation of charge between two plates, supercapacitors leverage a larger surface area and thinner dielectrics, allowing for significantly higher capacitance and energy storage capabilities.

Supercapacitors can store and release energy rapidly, making them ideal for applications requiring quick bursts of power. The enhanced capacitance of supercapacitors, often thousands of times greater than that of traditional capacitors, enables them to bridge the gap between conventional capacitors and batteries. This makes them suitable for applications where batteries might be too slow to charge or discharge effectively, but where traditional capacitors lack sufficient energy storage.

Charging a supercapacitor with a battery

- Direct Charging: The battery is directly connected to the supercapacitor with a resistive element to limit inrush current. The current decreases as the supercapacitor charges until the voltages match. This method is simple but can be inefficient due to energy losses and potential overheating.

- Controlled Charging: A charging circuit, such as a DC-DC converter, regulates the charging process, optimizing efficiency and protecting the components. This method is suitable for applications requiring precise energy management and longer component lifespan.

Charging a supercapacitor via energy harvesting

- Solar energy harvesting: Solar panels convert sunlight into electrical energy. A Maximum Power Point Tracking (MPPT) controller optimizes energy extraction. This method is effective for outdoor sensors and autonomous devices.

- Indoor light harvesting: Photovoltaic cells capture artificial indoor lighting to charge supercapacitors. This method powers small electronic devices like sensors and IoT devices used indoors.

- NFC energy harvesting: Near Field Communication (NFC) enables devices to harvest energy from NFC readers or devices. This energy charges supercapacitors in low-power devices like wearables and contactless payment systems, ideal for close-range wireless power transfer and data communication.

Both battery and energy harvesting methods offer unique advantages. Battery charging is reliable and controllable, while energy harvesting is sustainable and maintenance-free, suitable for various environmental conditions and application requirements.

Charging a

supercapacitor

Energy density

of supercapacitors

The energy density of supercapacitors, while impressive in terms of power delivery, typically falls short compared to traditional batteries. This limitation arises from their reliance on electrostatic charge storage rather than chemical reactions. Consequently, supercapacitors excel in applications requiring rapid energy discharge but may lack the capacity for extended energy storage.

However, ongoing research aims to enhance the energy density of supercapacitors through advancements in electrode materials, device architectures, and electrolyte formulations. These efforts seek to bridge the gap between the high power density and lower energy density of supercapacitors, expanding their utility in diverse fields such as transportation, renewable energy integration, and portable electronics.

The terms “supercapacitors” and “ultracapacitors” are often used interchangeably to refer to the same energy storage devices. Both supercapacitors and ultracapacitors operate on the principle of electrostatic charge storage rather than chemical reactions, allowing them to charge and discharge rapidly. Although, some distinctions exist in terminology and historical usage.

“Ultracapacitors” was the earlier term used to describe these devices, emphasizing their ultra-high capacitance and rapid energy transfer capabilities. Over time, “supercapacitors” gained prominence as a more general term encompassing various capacitor technologies with high energy density. In essence, the difference between the two lies more in terminology and historical usage rather than fundamental design or operation.

What is the difference

between supercapacitors and ultracapacitors?